|

Engineering

safety into a convertible

BY NEAL WHITE, MOTOR NEWS

MEDIA, (Orange County Register March 16, 2006)

Convertibles pose unique challenges to engineers due to the fact the vehicle

does not have a roof. In

sedans and coupes, the structure includes three main supports: the A-pillar,

which to used to hold the

front windscreen and the front part of the door the B-pillar, which serves

as the brace at the end of the

front door, and in the case of sedans, the beginning of the second door and

the C-pillar, which

supports the rear windscreen at the rear of the car.

In addition to providing enhanced structural Integrity for the vehicle, the

three pillars also support the

roof in the event of a rollover. When engineering the 2006 Volvo C70

four-passenger convertible,

safety had to be part of the design.

“From the outset, we wanted to build one of the safest convertibles on the

market," said James Hope,

product communications manager “We took our Volvo DNA and evolved it."

To achieve that goal, the lack of a fixed roof was compensated for with

reinforcements and sophisticated

technology. In a side collision, where the B-pillar is exposed to

considerable force, engineers had to build

protection in a different way. In the case of the 2006 C70, the forces were

channeled forwards, backwards

and downwards into the body structure, where an integrated system of members

and reinforcements

interact to help keep the passenger compartment as intact as possible. The

B-pillars have extra

reinforcements and are linked to each other through a powerful, transverse

floor member. In fact, a

total of five transverse members - which help absorb energy and protect the

passenger compartment -

are placed along the length of the car.

The doors were also strengthened through the use of a diagonally mounted

steel beam, which helps

prevent intrusion into the passenger compartment. At the same time, they

were designed to hook onto

the B-pillars and remain closed during a crash. The A-pillars were

strengthened through the use of

extra-high-strength steel and hydroforming, a production process in which a

tube is shaped on the

inside with the aid of water under very high pressure.

In the event of a head-on or offset collision, the C70 structure is divided

into zones, each with different

deformation properties. The outer zones account for most of the

deformation. The more the collision

forces approach the passenger compartment, the less the material is

deformed.

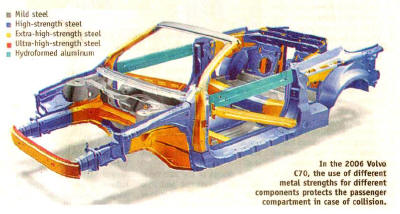

To ensure that each zone has the right characteristics, the quality of the

steel is varied. Four different

types of steel are used, including three different grades of high-strength

steel: high-strength steel,

extra-high-strength and ultra-high-strength. While the zones are designed to

absorb energy, the reinforced structure also allows energy to be channeled

away from the cabin.

In addition to the structure, the new C70 includes a number of safety

features. Volvo's side impact

protection system, which incorporates the safety design of the vehicle's

frame, also incorporates an

inflatable curtain. Mounted in the door, the curtain has an extra stiff

construction with double rows of

slats that are slightly offset from each other, allowing them to remain

upright and provide head

protection even with the window open.

The curtain also deflates slowly to provide protection should the car roll

over. Passengers in the front

seat also have side-impact air bags, designed to cover the chest and hip

areas. Both of these work

in conjunction with the seat-belt pretensioners (provided for all four

seating positions), to help provide

maximum protection.

The C70 convertible also is equipped with Volvos rollover protection system.

The ROPS system includes

powerful metal bars that come up behind the passengers in the rear seat to

provide extra protection

should the car roll over. Located behind the rear seat headrests, they are

basically unnoticeable unless

someone points them out.

Although the hardtop roof provides added protection (while also reducing

the risk of break-ins), it is

not the same as a conventional roof. The bars, which are part of ROPS, are

also designed to push

through the rear glass window if the top is up, providing added head

protection in the event of a

rollover - whether the top is up or down.

In the event of a rear-end collision, the structure also is designed to

deform in a controlled way and

is linked to the body sills to distribute the collision forces forward in

the body structure. The horseshoe

shaped member behind the rear seat and a double metal wall behind the

backrest contribute to

reducing the risk of intrusion into the passenger compartment.

The ROPS bars also are pushed upwards in a rear-end collision to reduce the

risk of the passengers

being hit by flying objects from behind. Additionally, the C70 incorporates

Volvo's whiplash protection

system. In the event of a rear-end collision, the backrest and head

restraints in the front seats follow

the movements of the occupant's body, providing support and helping reduce

the risk of neck injury

typically caused by rear-end collisions.

The C70 also is designed with a number of preventive safety features:

dynamic stability and traction

control, which helps keep the car on track and avoids skids; anti-lock

brakes with electronic brake force

distribution to the rear wheels; and automatic emergency brake assistance. |